When Amazon put the Echo on sale for Black Friday in 2018, it sold out of stock almost instantly. With such a huge demand for their product, it would have been foolish for the company to turn away customers and forgo revenue. Instead they allowed Echo devices to be backordered, so customers could place their orders and wait for them to be fulfilled when stock was available.

What is backordering?

Backordering is the process of allowing your customers to place orders even if you don’t have sufficient stock on hand. Businesses implement backordering when a sudden increase in sales means that products are getting sold faster than they can be stocked. It’s a common practice, used by retailers all over when they’re faced with a surge in demand.

The businesses that use just-in-time inventory management strategy, where the companies only receive goods when they’re demanded, thereby decreasing inventory holding costs have items backordered on a regular basis. Therefore they must accurately predict the customer’s demand within a stipulated amount of time. In such businesses or companies backordering is an essential and a crucial part in sustaining business operation.

Why is backordering important?

Backordering increases sales for your business and prevents your customers from going to your competitors. It also offers a few other essential benefits:

Customization

Since backordering involves passing the customer’s order along to your supplier, it’s easy to accommodate custom requests. For example, Harley Davidson allows its customers in the UK an option to build their own motorcycles. By using backordering instead of a standing inventory, the company has turned a convenient business decision into an appealing selling point for its customers.

Reduced costs

Backordering reduces the problem of overstocking products, which in turn reduces warehousing costs. For retailers that are just starting out, it makes it possible to spend less on starting inventory. It also frees up capital that would otherwise be tied up in stock and holding costs. For Example: Tesla, prefers to keep their inventory less and produce on demand, thereby reducing the amount of capital and risk tied up with excess inventory storage.

Less waste

Backordering reduces wasted inventory, because the faster turnaround means goods have less time to become damaged or obsolete. For example, if you’re a retailer who sells air conditioners, you get a surge in demand every summer. But once winter hits, the demand plummets. You don’t want to be left with unsold units over the winter, because they might be damaged by weather or be upstaged by newer models next summer. By using backordering, you can meet the summer demand with less risk.

Increased product and brand value

Some technology-intensive companies use backordering as a marketing gimmick, to increase the value of the product in the eyes of the customer. For example, the Samsung Galaxy S10 5G, which is one of the first phones to offer 5G support, is on backorder in the UK before its launch. The high number of backorders, indicate that the strategy helps to increase customers’ curiosity and desire to buy.

How does backordering work?

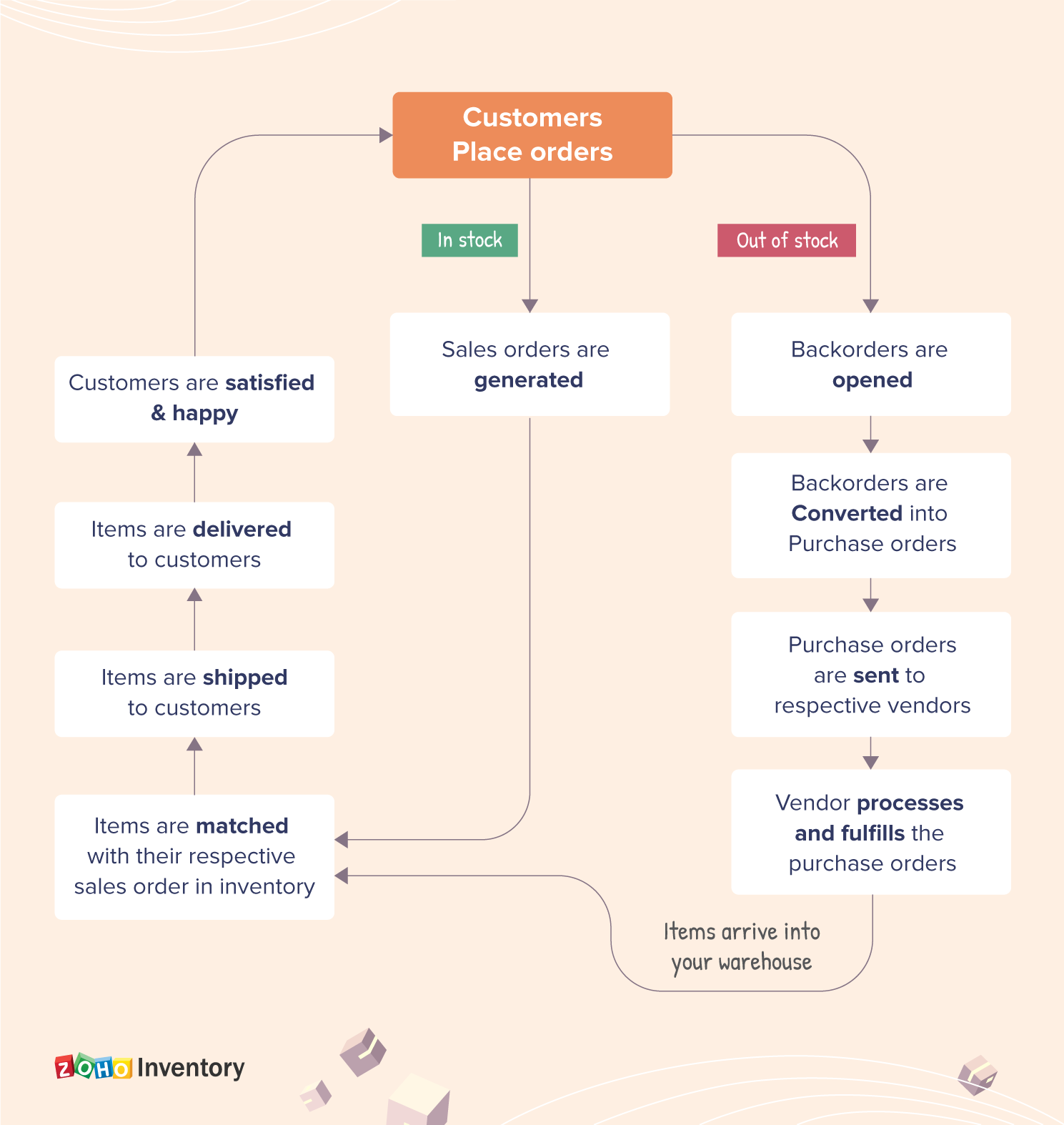

To understand how backordering works, let’s compare an order fulfillment process where

the items are in stock with one where the items are out of stock and being backordered.

In a scenario where the items ordered are in stock, this is the order fulfillment process:

- The customer places an order for an item.

- You generate a sales order for the item.

- You find the item in your inventory and match it with the sales order.

- You ship the item to the customer to fulfill the order.

In a backordering scenario, here is how the order fulfillment process works:

- The customer places an order for an item which is out of stock.

- You open a backorder for the item and convert the backorder into a purchase order for your vendor.

- You send the purchase order to your vendor.

- Your vendor fulfills your order. Once the item arrives at your warehouse, you ship it to your customer to fulfill their order.

Backordering is relatively simple when dealing with one out-of-stock item. But if you’re dealing with a stockout situation across several products, or you’re relying on backordering as your main inventory strategy, you need to be able to match each purchase order with the correct sales order before you begin the order fulfillment process. In order to manage your incoming items and outgoing sales simultaneously, it helps to have an inventory management system that can match up your sales and purchase orders for you.

Backordering helps you retain your customer base and ensure that your sales are doing well even when you don’t have much stock. It also benefits your business by reducing costs, reducing waste, increasing your product value, and allowing you to offer custom orders. With good customer service and an efficient inventory management system, you can make backordering a successful strategy for your business.