- HOME

- Know Your Tech

- What is supply chain management: A complete guide

What is supply chain management: A complete guide

- Last Updated : August 21, 2025

- 60 Views

- 10 Min Read

HIGHLIGHTS

- Supply chain management (SCM) is the engine behind cost savings, faster deliveries, and better service.

- This blog breaks down the key components of modern SCM, from planning and procurement to logistics and reverse logistics, while explaining how technologies like AI, IoT, and automation are reshaping operations.

- It also covers real-world examples, common challenges like poor visibility and demand forecasting issues, and best practices to build a resilient, data-driven supply chain.

In business, success often depends on one key element: how effectively you manage your supply chain. A well-structured supply chain is more than just the movement of goods; it’s a key driver of operational efficiency, cost savings, and customer satisfaction. For those overseeing operations, logistics, and procurement, supply chain management (SCM) isn't just a set of tasks, it's a powerful tool that supports growth and competitiveness.

Businesses that manage their supply chains effectively are the ones that stay ahead of the curve. Whether you're working to reduce costs, improve processes, or deliver better service, mastering SCM offers new ways to drive growth and achieve better results.

In this blog, we’ll break down the essential elements of SCM and show you how it can improve your business.

What is supply chain management?

Supply chain management (SCM) refers to coordinating all the activities involved in moving goods, services, and information from suppliers to customers. It ensures the smooth flow of raw materials, works-in-progress, and finished goods while managing supplier relationships, production, inventory, and distribution. Technically, SCM involves sophisticated systems and technologies that enhance visibility, automate processes, and optimize the supply chain to achieve efficiency and cost-effectiveness.

SCM often integrates aspects like procurement, logistics, and production using the internet of things (IoT), artificial intelligence (AI), machine learning, and cloud-based software to improve data sharing, decision-making, and overall performance. The goal is to deliver the right product to the right customer at the right time and at the correct cost.

Why is supply chain management important?

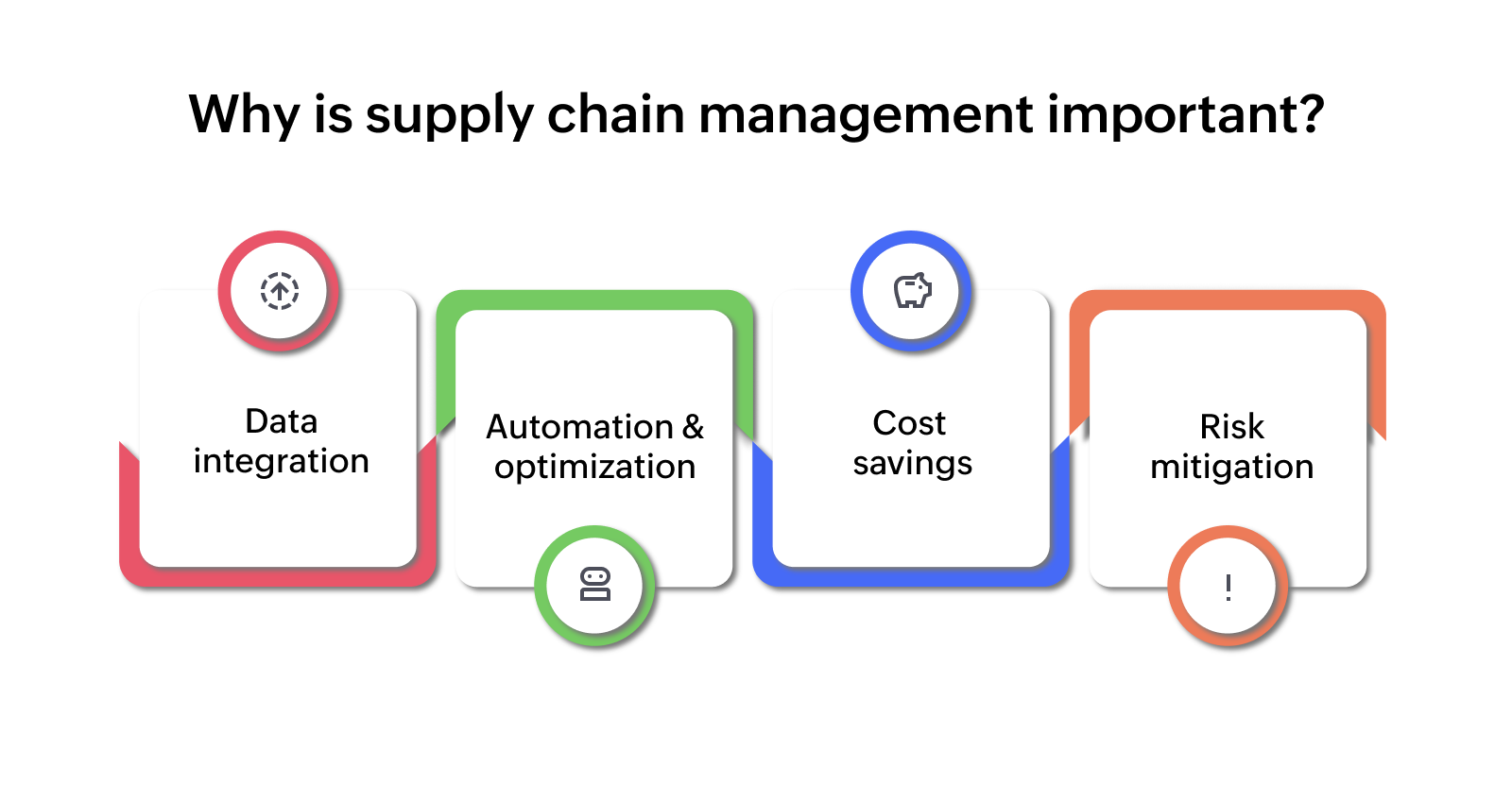

SCM is important for driving down operational costs, improving customer satisfaction, and increasing business agility. By optimizing processes and simplifying operations, SCM helps businesses respond more effectively to market demands and maintain a competitive edge.

Data integration and visibility: Real-time data from various touchpoints within the supply chain (suppliers, manufacturers, warehouses, distributors) helps companies make informed decisions. Technologies such as RFID (radio frequency identification) and IoT allow inventory and products to be tracked across the supply chain, ensuring transparency and quicker response times.

Automation and optimization: Automation tools like robotic process automation (RPA) and AI-driven analytics enable businesses to simplify repetitive tasks, optimize routes, manage inventory, and forecast demand with higher accuracy.

Cost savings and efficiency: By automating and integrating key supply chain functions, companies reduce manual errors and inefficiencies, ultimately cutting down on operational costs. AI algorithms and machine learning optimize inventory, minimize stockouts, and help balance supply and demand.

Risk mitigation: SCM technology aids in detecting disruptions early. Companies can use predictive analytics and simulation tools to assess potential risks and adjust strategies before problems escalate.

As businesses adapt to new demands and market conditions, understanding the different types of supply chains is essential for streamlining processes and driving better performance.

Types of supply chains

Supply chains aren't all the same; depending on your business model, objectives, and market needs, you may use different types of supply chains. Below are the most common types of supply chains:

Traditional supply chain

The traditional supply chain follows a linear approach, where goods move from suppliers to manufacturers, distributors, and finally to the end customers. In this model, each stage of the supply chain operates in a sequential manner, which can sometimes create inefficiencies due to the lack of real-time information exchange.

Key challenge: Limited flexibility and reliance on manual intervention at each stage

Example: A small-scale manufacturer that sources raw materials from local suppliers, produces the products in-house, and distributes them directly to end consumers

Global supply chain

A global supply chain operates across international borders, managing suppliers, production facilities, and customers in multiple countries. This type of supply chain is complex due to the challenges of dealing with different regulations, currencies, tariffs, and logistics constraints across borders.

Key challenge: Managing the risk of geopolitical events, tariffs, and customs delays

Example: A company that sources components from multiple international suppliers, assembles products at a regional facility, and distributes them to various global markets

Lean supply chain

The lean supply chain focuses on efficiency by reducing waste at every stage of the supply chain. It uses techniques like just-in-time (JIT) inventory to ensure that production processes are aligned with demand, reducing excess stock and eliminating bottlenecks.

Key challenge: Risk of stockouts due to over-reliance on lean principles and minimal inventory buffers

Example: A company that orders parts from suppliers only when required for production, minimizing storage costs while ensuring timely deliveries

Agile supply chain

An agile supply chain is built around flexibility, allowing companies to respond to changes in demand or supply disruptions quickly. This type of supply chain is characterized by the ability to rapidly adjust production schedules and sourcing strategies to meet market fluctuations, customer preferences, or unexpected events.

Key challenge: Higher operational costs due to the flexibility and adaptability required

Example: A business in the fashion industry that adjusts its inventory and production based on customer preferences and shifting market trends, ensuring quick turnaround times for new collections.

Each type of supply chain offers distinct advantages based on specific business needs, whether it's efficiency, flexibility, or global reach. The choice of supply chain model depends on factors like product type, market conditions, and organizational goals.

The role of technology in supply chain management

The increasing use of technology in SCM is evident in this Gartner survey, which found that 73% of companies made significant changes to their supply chains in recent years, reflecting the growing emphasis on flexibility and technology-driven processes.

Technology is essential for overcoming supply chain challenges by optimizing processes, cutting expenses, and improving strategic choices. Tools like real-time tracking, automation, and AI help streamline operations, increase visibility, and allow businesses to respond quickly to market changes.

Here's how technology is reshaping supply chain management:

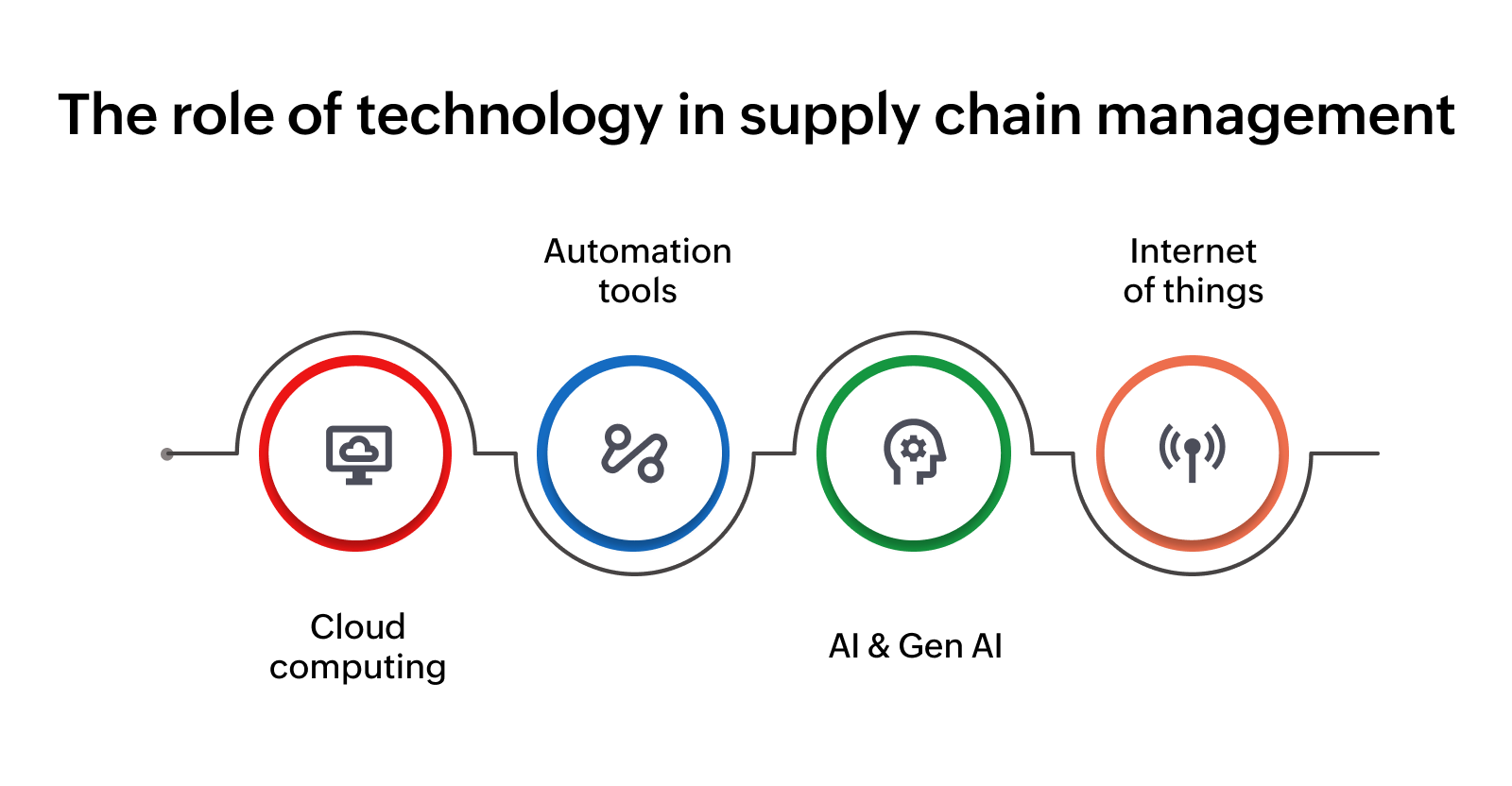

Cloud computing

Moving supply chain operations to the cloud improves visibility and allows teams and suppliers to share real-time data. This means everyone can access the latest information, which helps make faster decisions and improves collaboration.

Automation tools

Robotic process automation (RPA) can reduce the need for manual work by automating repetitive tasks like order processing, invoicing, and inventory management. This helps reduce errors and frees up employees to focus on higher-priority tasks.

Artificial intelligence (AI) and generative AI (GenAI)

AI and GenAI are transforming supply chain management by enhancing inventory management and improving demand forecasting. These technologies analyze large datasets to generate insights and make accurate predictions, helping prevent issues like overstocking or stockouts.

Internet of things (IoT)

IoT devices help track goods moving through the supply chain. This real-time data allows businesses to monitor shipments, check conditions, and optimize delivery routes, reducing losses and delays.

EPT Global Logistics, a global logistics and freight forwarding company, is a real-world example of technology driving supply chain success. To simplify its complex operations, EPT used Zoho Creator, a low-code application development platform, to build a custom ERP solution tailored to its needs. The result? A centralized system called Prowise that simplifies customer management, inventory, HR, reporting, and more.

This digital transformation led to a 2.5x increase in revenue, a 15% boost in productivity, and over 10 hours saved per month in manual work.

By using platforms like Zoho Creator and integrating automation, analytics, and IoT into your supply chain, you can gain a competitive edge while cutting costs and improving customer satisfaction.

Key elements of modern supply chain management

To improve SCM and operational performance, focusing on essential components like procurement, inventory management, and supplier relationships is important. Using advanced technologies and tools in these areas can significantly boost efficiency and enhance the overall agility of your supply chain.

Planning and forecasting

Effective planning and forecasting are powered by AI and machine learning algorithms that predict demand based on historical data, market trends, and external factors. This data is integrated into advanced planning systems (APS) to optimize production schedules and inventory levels.

Machine learning-based demand forecasting: Algorithms predict future demand by analyzing patterns from historical sales data, allowing businesses to plan production and procurement more accurately.

Scenario simulation: APS allows businesses to simulate various demand scenarios to adapt to real-time changing conditions.

Procurement and sourcing

In modern SCM, procurement is automated and managed through eProcurement platforms, which help companies source materials from reliable suppliers based on cost, quality, and lead time. Supplier relationship management (SRM) systems are used to evaluate supplier performance and build long-term, strategic partnerships.

Automated procurement: Tools automatically place orders, track deliveries, and manage supplier communication, improving procurement efficiency and reducing manual intervention.

Supplier performance tracking: SRM systems collect real-time data from suppliers to measure reliability and quality.

Production

Production management relies heavily on manufacturing execution systems (MES) and IoT devices that monitor every stage of production. These systems provide real-time data on equipment performance, material availability, and production progress.

IoT-driven production monitoring: Sensors track machine performance, material consumption, and product quality in real time, reducing downtime and enhancing operational efficiency.

Lean manufacturing: Technologies that monitor waste and optimize processes to reduce costs, improve product quality, and meet demand more precisely.

Logistics and transportation

Logistics management uses transportation management systems (TMS) to plan and optimize delivery routes, monitor real-time shipments, and efficiently manage inventory movement. These systems use data analytics to reduce transportation costs and improve delivery accuracy.

TMS with route optimization: TMS automates transportation planning and optimizes delivery routes based on real-time traffic and weather data.

Warehouse automation: Warehouse management systems (WMS) integrate with robotic systems and automated sorting technologies to enhance picking accuracy and speed.

Inventory management

Real-time inventory tracking and optimization are crucial for maintaining the right stock levels at the right time. Technologies like RFID, barcoding, and IoT sensors allow businesses to monitor inventory in real time, reducing overstocking and stockouts.

AI-powered inventory optimization: Machine learning models calculate optimal inventory levels by analyzing demand patterns, seasonality, and lead times.

Real-time tracking: RFID and IoT sensors provide live data on stock levels, helping to avoid delays in production and order fulfillment.

Return and reverse logistics

Efficient reverse logistics ensures that returned goods are handled promptly and accurately, contributing to customer satisfaction. Automated returns processing and blockchain for tracking the movement of returned items can enhance transparency and reduce errors.

Reverse logistics automation: Returns management software simplifies the process, tracking product returns, processing refunds, and communicating with customers.

Blockchain for returns tracking: Blockchain offers a secure and transparent way to trace the lifecycle of returned products. While it provides significant benefits in terms of security and accountability, its widespread implementation in returns tracking is still limited and largely in the early stages of adoption.

Technology and automation

At the core of modern SCM are integrated platforms and automation tools connecting all supply chain parts. These systems help automate routine tasks, increase supply chain visibility, and enable real-time decision-making.

Supply chain visibility platforms: These platforms integrate data from all supply chain stages to provide a comprehensive view, enabling better decision-making and quicker responses to disruptions.

Robotic process automation (RPA): RPA automates routine tasks like invoicing and order processing, allowing your team to focus on higher-value activities.

Integrating these key elements and utilizing modern technologies, businesses can refine their supply chain processes, improve operational effectiveness, and better adapt to fluctuating market demands.

Challenges in supply chain management

Managing a supply chain can be complex, and several issues often arise that can impact your business operations. Some of the common challenges include:

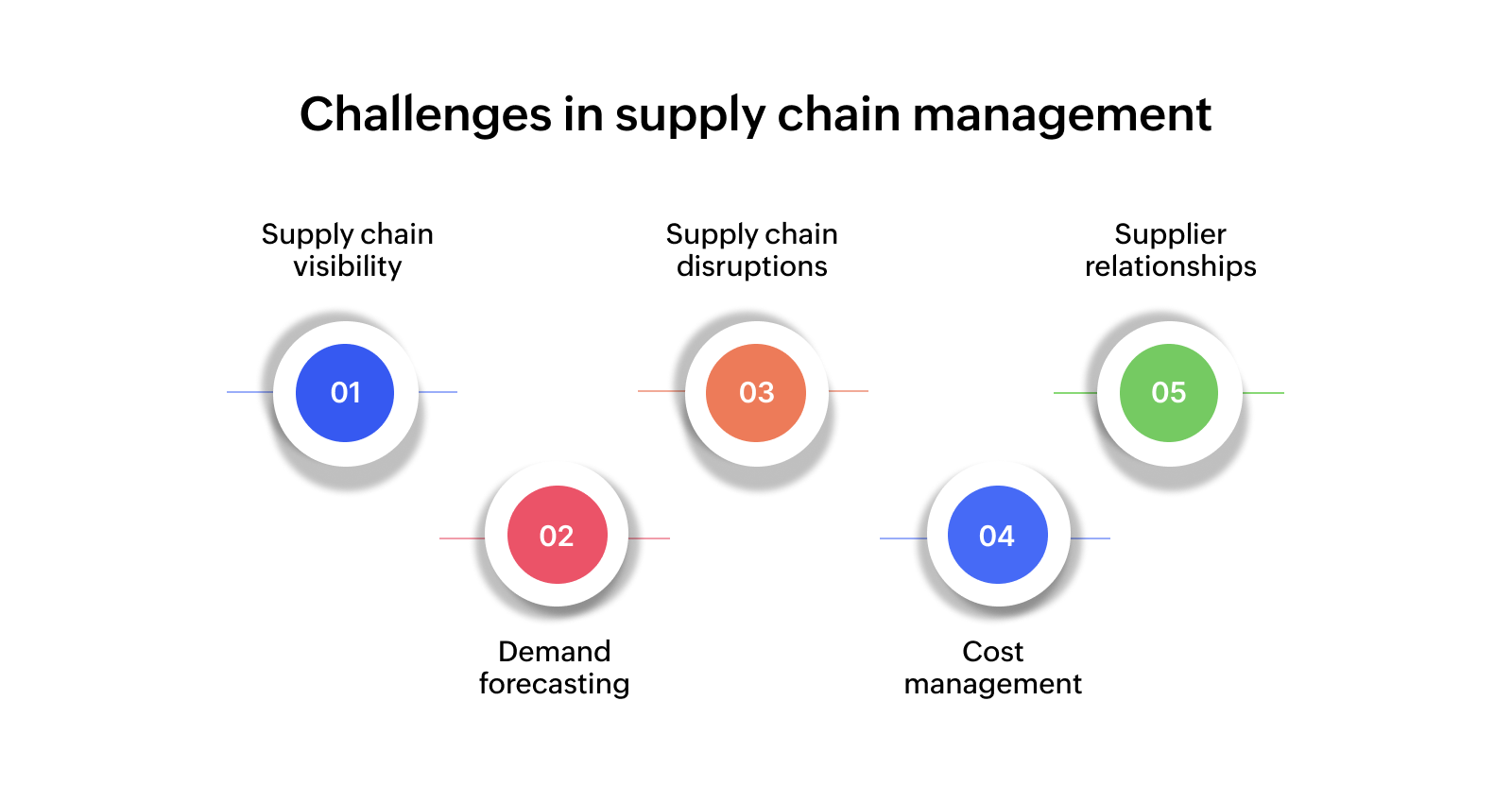

Supply chain visibility

A major issue businesses face is a lack of transparency in the supply chain. Without the ability to track inventory, shipments, and vendor performance in real time, you may experience delays, stockouts, or disruptions to your production schedules.

Demand forecasting

Predicting demand is difficult, and poor forecasting can lead to problems. If you overestimate demand, you could end up with too much stock and added costs. On the other hand, underestimating demand means you might run out of inventory, lose sales, and frustrate customers.

Supply chain disruptions

External events, such as natural disasters or economic shifts, can quickly disrupt supply chains. Without a solid plan to manage these disruptions, your business may face delays or increased costs.

Cost management

As transportation, raw materials, and labor costs rise, businesses must manage expenses carefully. Keeping costs under control without compromising on product quality or service requires constant monitoring and effective planning.

Supplier relationships

If your suppliers face issues, such as delays, quality problems, or pricing changes, it can have a direct effect on your business. Developing strong relationships with reliable suppliers and having backup options is important to minimize risks.

Overcoming these challenges requires solid planning, building strong supplier relationships, and finding ways to improve visibility within the supply chain to ensure smoother operations.

Best practices for effective supply chain management

By adopting the right strategies, businesses can optimize their supply chain processes, enhance collaboration, and drive long-term success.

Here are some essential practices to help achieve these goals:

Data-driven decision-making: Using data to guide decisions is essential. It allows you to make informed choices that align with your goals and improve performance by tracking metrics like inventory levels, supplier lead times, and demand forecasts.

Build strong relationships with suppliers: Cultivating long-term relationships with reliable suppliers ensures consistent product quality and timely deliveries. Having backup suppliers ready to step in, if needed, can also prevent issues that arise from unexpected supplier problems.

Collaborate across teams: Supply chain management involves several departments, from procurement to logistics. Ensuring that all teams are aligned and working together helps reduce delays and improve coordination throughout the supply chain.

Effective inventory management: Properly managing your inventory is key to keeping costs down and meeting demand. Consider using just-in-time (JIT) inventory methods or investing in software to help manage your stock more efficiently and reduce waste.

Focus on continuous improvement: Regularly review and refine your processes. Continuously looking for ways to improve your supply chain will help keep it running smoothly and help you respond quickly to changes in the market.

By following these best practices, you can ensure your supply chain operates efficiently, reduces costs, and remains adaptable to changing needs.

Simplifying supply chain management with custom solutions

Managing a supply chain efficiently is no easy feat. As a project manager or CEO, you constantly face challenges like coordinating suppliers, managing inventory, and minimizing delays, all while trying to reduce costs and improve service quality. A simplified process can alleviate these concerns and lead to greater operational efficiency and profitability.

Zoho Creator can help turn this challenge into an opportunity. As an AI-powered low-code platform, you can use it to quickly build custom applications to automate and improve your supply chain operations. Zoho Creator gives you the flexibility to create solutions that fit your specific needs, without heavy reliance on IT, so your team can focus on scaling and driving results.

Stephen

StephenStephen is a product marketer at Zoho Creator. An avid writer, he plies his trade evangelizing low-code during the day and pens songs at night. Sneakerhead and sushi enthusiast too.