Every time you place an order with a store, there is a process that runs in the background until you finally receive your purchase. This process is called order management, which is basically keeping track of customers’ orders and handling the steps involved with fulfilling them. The process generally consists of accepting the order; picking, packing, and shipping the items mentioned in the order; and finally tracking them until they get delivered.

Read on to learn more about how order management works and how an efficient order management technique can help your business.

How does order management work: Order Management Process

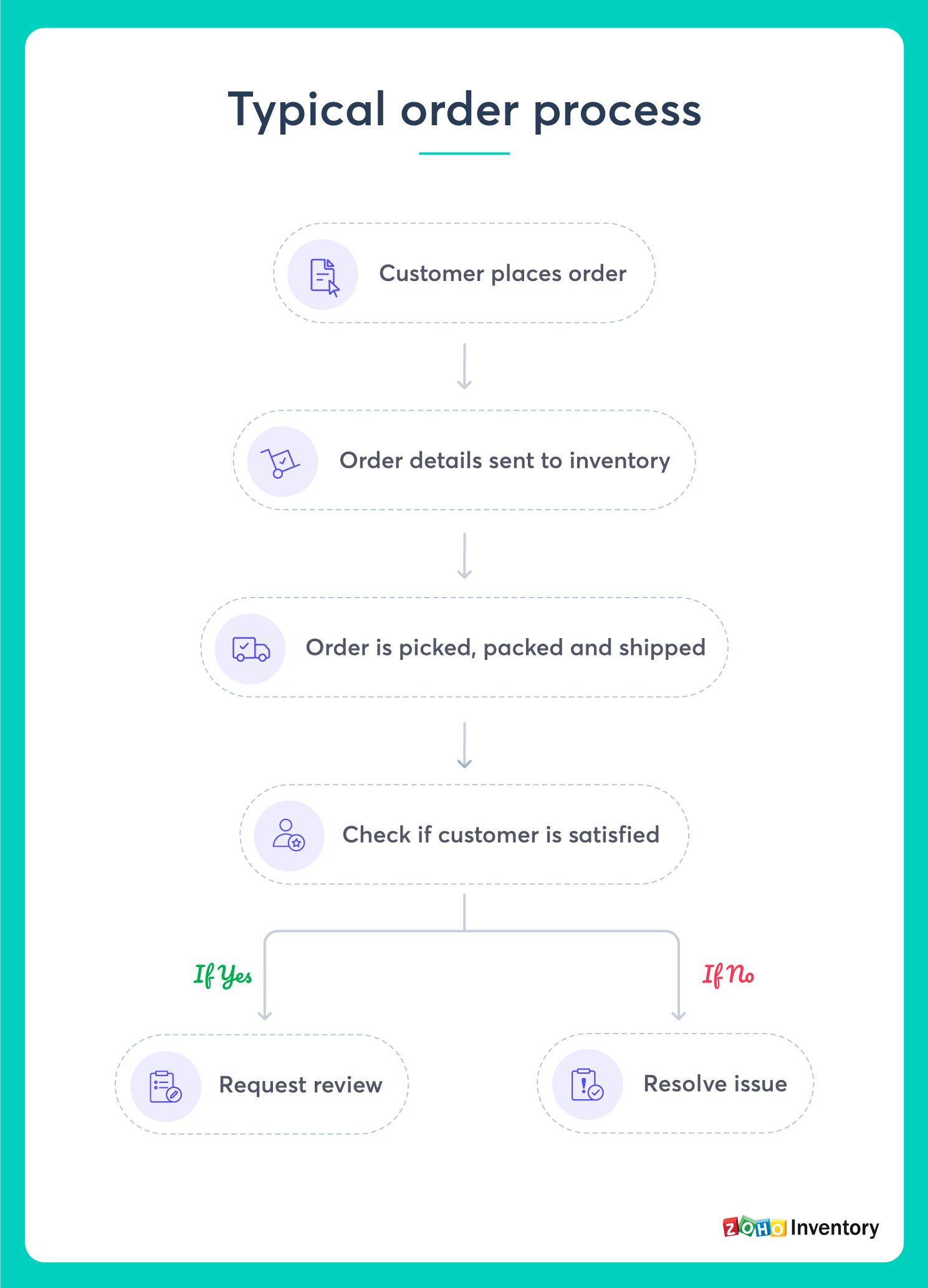

Order management processes start right after a customer places their order and pays for it. The details of the order are sent to the store’s inventory, where warehouse workers manage the picking, packing, and shipping. The process ends with the store checking in with the customer to figure out if they were happy with their purchase. Here are the steps of a typical process.

Most order management processes can be broken down into 3 stages: receiving a customer’s order, fulfilling the order, and then handling the after-sales processes. Let’s see how each stage works in detail:

Stage 1 – Receiving the customer’s order

The first stage of any order management process begins when a customer places an order with your business. Receiving includes accepting the order from the customer and collecting payment for it. After this is done, the details of the purchase are forwarded to your warehouse so your staff can start working on getting the products ready for shipment.

Stage 2 – Fulfilling the customer’s order

In the second stage, you actually fulfill your customer’s order. This stage can be split into 3 different steps:

Step 1 – Picking

Fulfilling an order starts with the picking process, in which the items are retrieved from the warehouse. Warehouses are usually lined with shelves that are each stocked with different types of products, so warehouse workers need to be able to pick the right items for an order quickly and accurately. Once the items have been picked, they are sent to a packing station to be packed.

Step 2 – Packing

The packing station has more responsibilities than just packing items and sending them off for shipping. They are also in charge of using the right packaging materials for each product so that it reaches the customer intact and in good condition, while also using resources efficiently. For example, extremely fragile items like glassware need to be packed with bubble wrap or air pillows, and in a properly-sized box to avoid wasting packing material.

Step 3 – Shipping

After you’ve picked and packed the correct order, the next step is to ship it. The warehouse employees working at the shipping station typically take care of 3 tasks:

- Attaching the applicable shipping label and invoice to the order

- Marking the order as shipped in all of your sales channels

- Sending out shipping confirmation and order tracking emails to the customer

Picking, packing, and shipping can only happen in that order if your business has the necessary products in stock. So what do you do when a customer places an order for a certain product, but you’re out of stock? In cases like this, businesses are left with two choices: they can either turn the customer away or postpone the order delivery to a later date using backordering or dropshipping.

For backordering, the business places a purchase order with their supplier for the product that is out of stock. The supplier will give the business a date when they will receive the new stock, and in turn the business gives their customer a tentative date to expect to receive their order. With dropshipping, the business forwards the customer’s order to the supplier, who delivers the product directly to the customer without sending it to the business first.

Stage 3 – Handling the post-sales processes

The last stage of order management is handling the after-sales processes. This is where businesses follow up with customers to receive feedback and make sure that they are satisfied with their purchase, and to manage any returns and refunds if they are not.

All three stages together make up a typical order management process. Some businesses like to customize their order management strategy to suit their needs better. Order management is also applicable for businesses that offer services instead of goods, although the process is slightly different. For instance, consider a mobile network provider. Instead of having to pick, pack, and ship products, a mobile network company has to receive each customer’s request to activate a network, and then set it up on the customer’s mobile phone.

What makes order management essential for businesses?

An organized and well-planned process for managing orders can do wonders for a business’ cashflow and inventory. It can save time and money, tell you whether the different parts of your company are working together well, and help you forecast the demand your business will receive. Let’s take a look at each of these reasons.

Since every order management process is itself made up of several individual processes that need to coordinate with each other from start to finish, it can help give you an idea of whether the different parts of your business are working together or not. This is important so that you keep your business running like clockwork and deliver orders quickly, accurately, and efficiently with minimal chances of error. Therefore, a streamlined process can be translated into higher customer satisfaction.

Another benefit of using an order management process is that it can help you learn to predict the level of demand you will receive. Predicting your demand will help you avoid overstocking and understocking, because you will know just how much of each product you’ll need to supply to your customers. This keeps you ready to sell your customers the products they want, when they want them. Since forecasting your demand gives you an outline of your business’ requirements and expenses, you can also use this information to chalk out a budget to follow. Over time, sticking to this budget will help your business’ cashflow too, so predicting your demand is good for your inventory, customer retention, and profitability.

Everything from accepting orders and keeping track of them to fulfilling them and taking care of the after-sales activity is part of an order management process. A proper order management technique that helps each process follow a fixed budget, keeps the inventory well-organized, and saves time and money should be at the top of every warehouse’s list of priorities. If you haven’t already, analyze your business and see if you can benefit from an order management process.